EDM Wires

EDM wire Features:

- Very good straightness, excellent in auto threading applications, especially in Japanese and German wire cutting machines

- Excellent Surface Finish

- Good Roundness

- Inline Japanese Continuous Annealing Technology ensures a stable and uniform tensile strength preventing wire breakage.

- Manufactured with a high precision of wire diameter tolerance of +0.000 / -0.002 mm with smooth surface free from flaws or irregularities

- Higher Cutting efficiency

| Sr. No | Wire Diameter (mm) |

Diameter Tolerance (mm) |

Wire Grade | Tensile Strength (N/mm 2) |

Elongation (%) |

Available Spool Types |

| 1 | 0.10 | + 0 , - 0.002 | Soft Semi Hard Hard |

450-550 550-750 >980 |

>25 > 10 ≤ 3 |

P5, DIN 125, DIN 160, Japax |

| 2 | 0.15 | + 0 , - 0.002 | Soft Semi Hard Hard |

450-550 550-750 >980 |

>25 > 10 ≤ 3 |

P5, DIN 125, DIN 160, Japax |

| 3 | 0.20 | + 0 , - 0.002 | Soft Semi Hard Hard |

450-550 550-750 >980 |

>25 > 10 ≤ 3 |

P5, DIN 125, DIN 160, Japax |

| 4 | 0.25 | + 0 , - 0.002 | Soft Semi Hard Hard |

450-550 550-750 >980 |

>25 > 10 ≤ 3 |

P5, DIN 125, DIN 160, Japax |

| 5 | 0.30 | + 0 , - 0.002 | Soft Semi Hard Hard |

450-550 550-750 >980 |

>25 > 10 ≤ 3 |

P5, DIN 125, DIN 160, Japax |

| ALLOY CODE: A1 - CuZn40, A2 - CuZn37, A3 - CuZn35 | ||||||

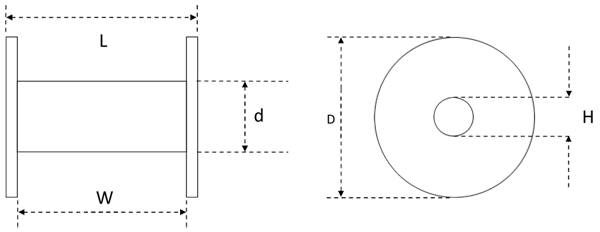

| Spool Type | (D) mm | (d) mm | (L) mm | (W) mm | (H) mm | Net Wt / Spool (kg) |

| DIN 125 | 125 | 80 | 125 | 100 | 16 | 3.5 |

| DIN 160 | 160 | 100 | 160 | 130 | 22 | 7 |

| DIN 200 | 200 | 125 | 200 | 160 | 22 | 10 |

| DIN 250 | 250 | 160 | 200 | 160 | 22 | 20 |

| P - 5 | 160 | 90 | 115 | 90 | 20 | 5 |

| P - 10 | 200 | 90 | 134 | 110 | 30 | 10 |

| P - 15 | 250 | 110 | 140 | 110 | 32 | 20 |

| Japax | 130 | 60 | 36 | 28 | 12.5 | 1.5 |

| Note: These spool dimensions are provided as general information, and are typical dimensions only. Spool manufacturers are not completely consistent with these dimensions. | ||||||

| No. | Process Type | Wire Type | |||

| Soft | Semi Hard | Hard | |||

| 1 | Straight cutting | 1 Pass Cutting | Not recommended | Good | Excellent |

| Straight cutting | 2 Pass Cutting (Rough +Finish) |

Not recommended | Not recommended | Excellent | |

| Straight cutting | 3 Pass Cutting (Rough +Finish + Refinish) |

Not recommended | Not recommended | Excellent | |

| 2 | Relief Cutting | 1 Pass Cutting relief under 10° | Not recommended | Good | Excellent |

| Relief Cutting | 1 Pass Cutting relief under 10° to 20° | Good | Excellent | Not recommended | |

| Relief Cutting | 1 Pass Cutting relief over 20° | Excellent | Good | Not recommended | |