Resistance Welding Products

Spot Welding Electrode Caps

Spot Welding Electrode Caps

Spot Welding Electrode Caps complying to standards like ISO 5821 or Customized as per customer's specifications.

Components from Special Copper Alloys.

Nut and Stud Welding Electrodes

Nut and Stud Welding Electrodes

In Class I and Class II alloys.

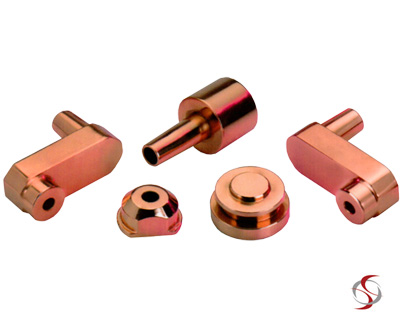

Swivel Head Electrodes, Button Tips, Socket and Threaded Tips

Swivel Head Electrodes, Button Tips, Socket and Threaded Tips

Electrodes

Electrodes

Standard and Customized Electrodes in Cu.Cr., Cu.Cr.Zr. and CuW (Tungsten) for Spot and Projection Welding applications.

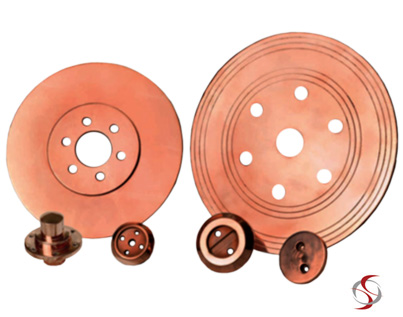

Seam Welding Wheels

Seam Welding Wheels

Weld wheels customized as per customers' drawings.

In Class I and Class II alloys.

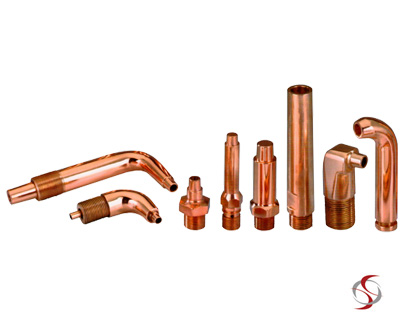

Shanks and Adapters

Shanks and Adapters

Straight, Single and Double bend.

Gun Arms and Holders

Gun Arms and Holders

In Class I and Class II alloys.

| Alloy | Group A RWMA Class 1 |

Chemical Composition | Hardness Minimum | Min. Elec. Conductivity | Tensile Strength Apprx. | Yeild Strength Apprx. | Elongation Apprx. |

| % | HRB | % IACS | ksi | ksi | % in 2 inch | ||

| Cu.Zr | C15000 | Cu Remaining Zr: 0.1-0.2 |

65 | 80 | 64 | 62 | 15 |

| Cu.Cd | C16200 | Cu Remaining Cd: 0.7-1.2 |

65 | 90 | 58 | 45 | 12 |

| Alloy | Group A RWMA Class 2 |

Chemical Composition | Hardness Minimum | Min. Elec. Conductivity | Tensile Strength Apprx. | Yeild Strength Apprx. | Elongation Apprx. |

| % | HRB | % IACS | ksi | ksi | % in 2 inch | ||

| Cu.Cr.Zr | C18150 | Cu Remaining Cr: 0.5-1.5 Zr: 0.02-0.20 |

70 | 75 | 70 | 55 | 21 |

| Cu.Cr | C18200 | Cu Remaining Cr: 0.6-1.2 |

70 | 75 | 70 | 55 | 21 |